LDPE RESINS

Contalen 0051 ACP

- Contalen 0051 ACP resins are LDPE homopolymers intended for blown and cast film extrusion and injection molding

- It has outstanding processing properties

- Contalen 0051 ACP is suitable for the film production of above 40 microns which are characterized by very good mechanical properties

- Due to the low melt flow index, it is characterized by very high mechanical strength and high puncture resistance

- Therefore, it is intended mainly for the production of heat-shrinkable films with very high strength, for which a very high degree of shrinkage is required

Find out more

Find out more

Parameters

| MFI | 0,3 g/10 min (±0,2 g/10 min) |

| Density | 0,92 g/cm3 (±0,02 g/cm3) |

Application

- Heat-shrinkable films

- Agricultural films

- Transport bags

- Co-extruded films

- Bags

- Industrial packaging

- Heat shrinkable hoods

- Construction films

- Waste bags

Benefits

Excellent processing properties

High mechanical strength

High puncture resistance

High degree of contraction

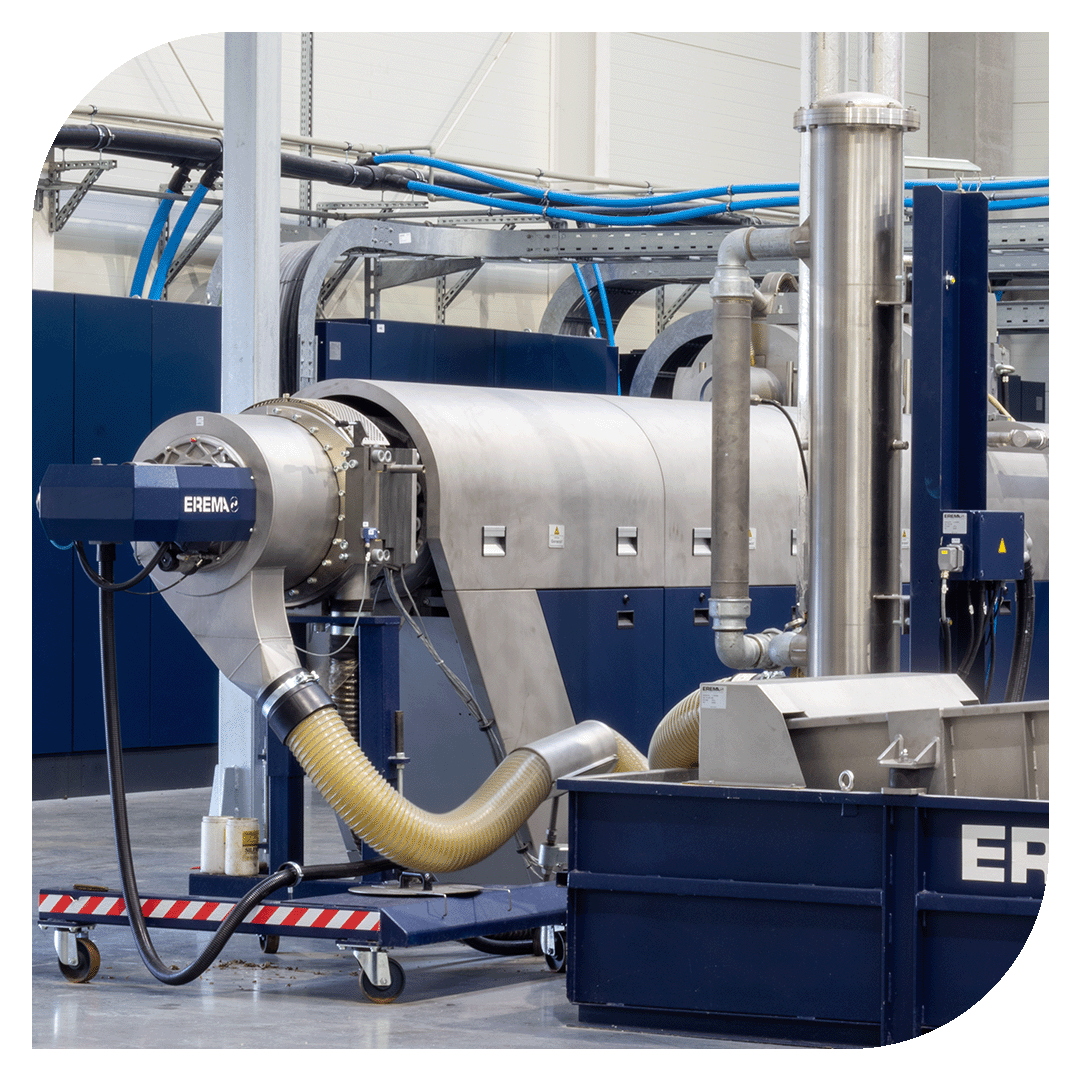

Proces technologiczny

TWOJA KORZYŚĆ NASZA TECHNOLOGIA

Parametry uzyskiwanych produktów są zbliżone do surowców oryginalnych i znacznie przewyższają właściwości regranulatów produkowanych metodami konwencjonalnymi.

01

Wysokoefektywny system mycia i suszenia płatka, system filtracji ciągłej

- Brak zanieczyszczeń w wyrobie gotowym

02

Kaskadowy system dwuwytłaczarkowy

- Wyższa gęstość i ciężar nasypowy regranulatu

- Zmniejszona ilość pęcherzyków gazu w wyrobie gotowym

- Brak konieczności używania osuszaczy

03

Innowacyjny system homogenizacji

- Bardzo wysoki stopień jednorodności

- Obniżona zawartość żeli

- Polepszone właściwości mechaniczne

04

Automatyczny system mieszająco-uśredniający

- Stabilizacja procesu produkcji wyrobu gotowego

Certificates

WE CARE ABOUT ENVIRONMENTAL PROTECTION

The EuCertPlast (now RecyClass) certificate obtained in 2020 confirms that our regranulates are produced from post-consumer waste and their origin is fully traceable.

As active members of plastics recycling associations, environmental protection is our constant concern.

Check all

+48 56 684 24 00

+48 56 684 24 00 info@conkret.com.pl

info@conkret.com.pl