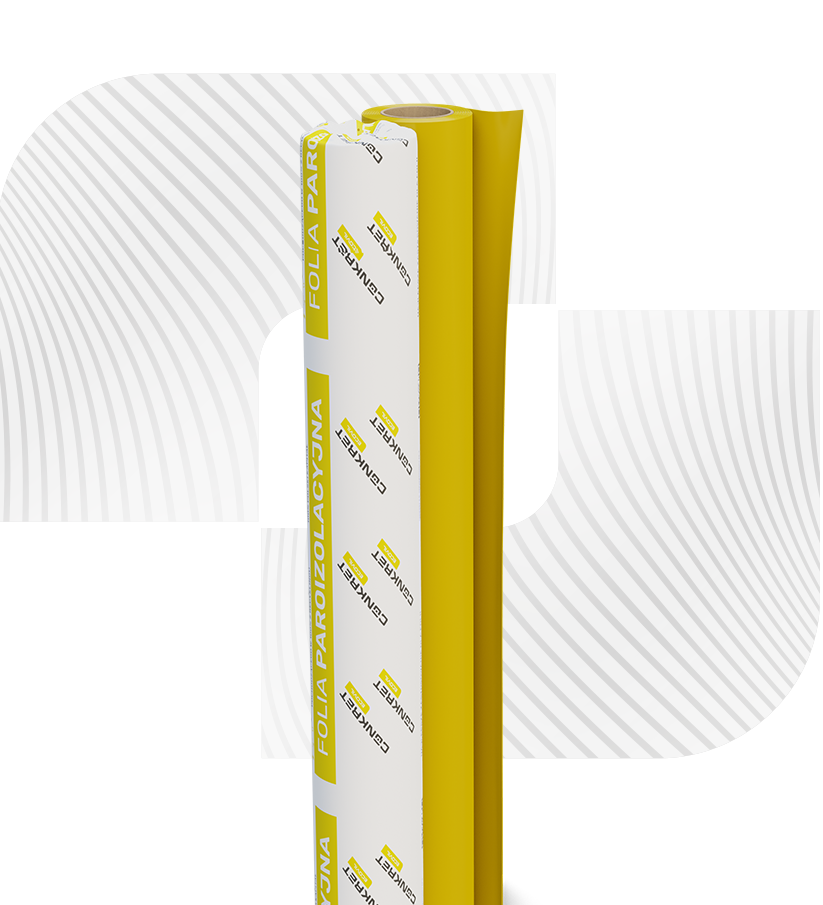

CONSTRUCTION FILMS

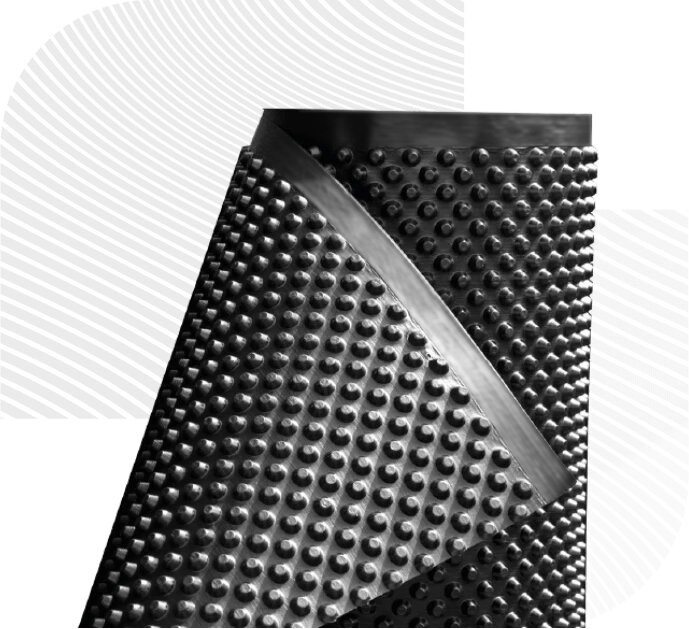

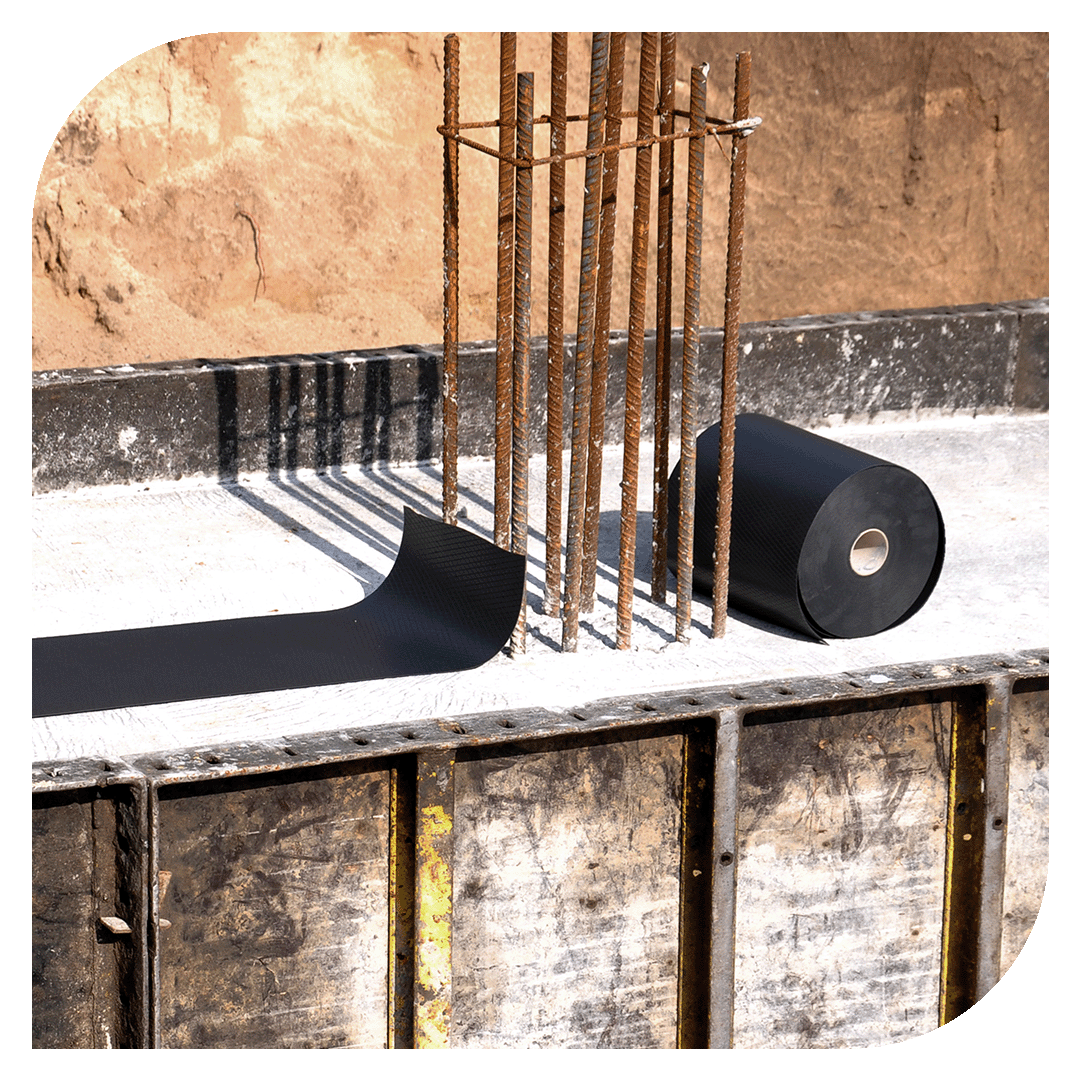

DIMPLED MEMBRANE DRENAXX 8

- Special dimples provide an air cavity between the building structure and insulation.

- This membrane ensures perfect drainage of water and water vapour, allowing drainage of the foundation wall

- It prevents the build-up of hydrostatic pressure in areas of the building that are prone to wetness

- The dimples additionally prevent the insulation from shifting as a result of subsidence of the backfilled soil

- High resistance to compression, tearing, breaking, abrasion and perforation

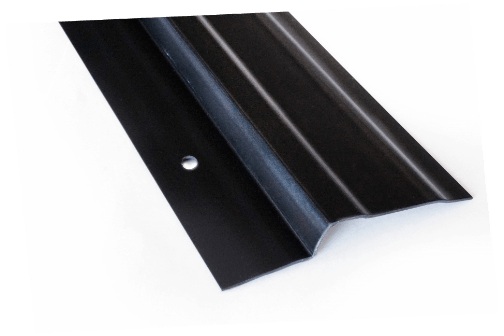

- A specially designed flange ensures the correct installation of the closing strip

- Does not contain hazardous substances (SVHC)

Find out more

Find out more

Parametry

| Grammage (g/m2) | 400 / 500 / 600 |

| Width (m) | 0,5 / 1 / 1,5 / 2 |

| Length (m) | 20 |

| Colour | black / graphite |

| Dimple height (mm) | 8 mm |

Application

- For use as a blinding layer, foundation wall protection and seepage layer in 2-shell constructions

- Constitutes a drainage layer for draining excess accumulated water along the wall

- Improves the ventilation properties of external walls and foundations

- Protects the thermal insulation of the building against plant roots and rodents

- Additional thermal insulation of building walls

Benefits

Waterproof

Durable

Broad scope of temperatures

Quality Warranty

Recycling

Flexible

Conformity with standards EN 13252

Reasonable price

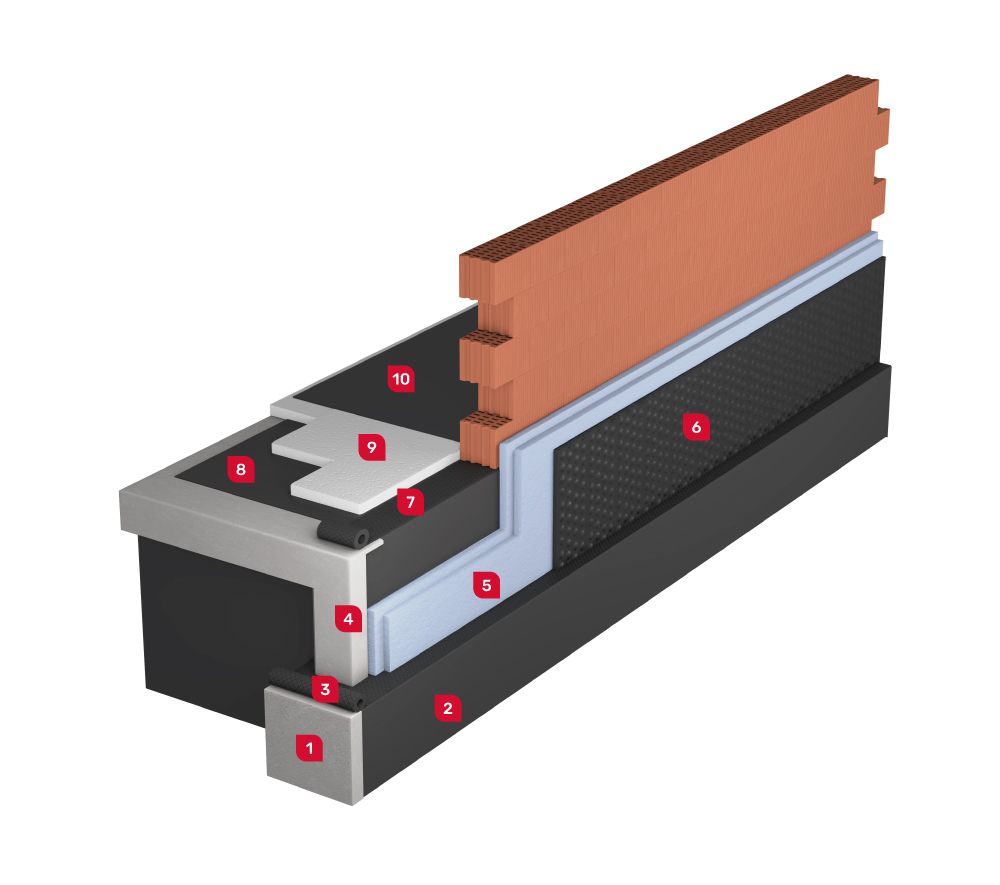

ASSEMBLY

DIAGRAM:

- Strip footing

- Vertical waterproofing of foundations

- Confol Gamma

- Foundation

- Foundation thermal insulation

- Drenaxx 8

- Confol Alfa

- Conbud / Conbud Plus / Hydro / Ecovil B

- Thermal insulation of the floor on the ground

- Ecobud polyethylene film

TRY OUR OTHER PRODUCTS

Conkret is a recycler and a leading manufacturer of regranulates as well as modern polyethylene films. We manage the entire technological process: starting with purchase of waste, its transport, segregation, regranulation to production of new finished products.

Our products are widely used in the furniture, packaging, construction, agricultural and gardening sectors.

More about usProces technologiczny

TWOJA KORZYŚĆ NASZA TECHNOLOGIA

Parametry uzyskiwanych produktów są zbliżone do surowców oryginalnych i znacznie przewyższają właściwości regranulatów produkowanych metodami konwencjonalnymi.

Wysokoefektywny system mycia i suszenia płatka, system filtracji ciągłej

- Brak zanieczyszczeń w wyrobie gotowym

Kaskadowy system dwuwytłaczarkowy

- Wyższa gęstość i ciężar nasypowy regranulatu

- Zmniejszona ilość pęcherzyków gazu w wyrobie gotowym

- Brak konieczności używania osuszaczy

Innowacyjny system homogenizacji

- Bardzo wysoki stopień jednorodności

- Obniżona zawartość żeli

- Polepszone właściwości mechaniczne

Automatyczny system mieszająco-uśredniający

- Stabilizacja procesu produkcji wyrobu gotowego

Certificates

WE CARE ABOUT ENVIRONMENTAL PROTECTION

The EuCertPlast (now RecyClass) certificate obtained in 2020 confirms that our regranulates are produced from post-consumer waste and their origin is fully traceable.

As active members of plastics recycling associations, environmental protection is our constant concern.

Check all

+48 56 684 24 00

+48 56 684 24 00 info@conkret.com.pl

info@conkret.com.pl