CONSTRUCTION FILMS

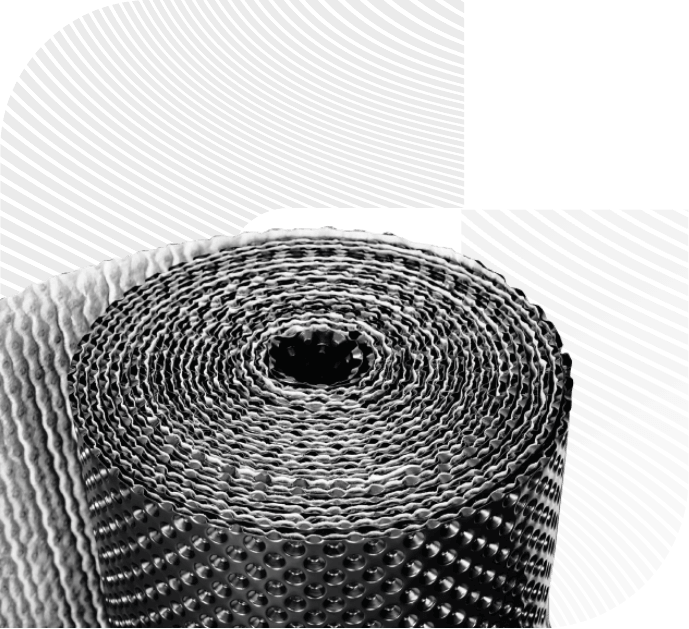

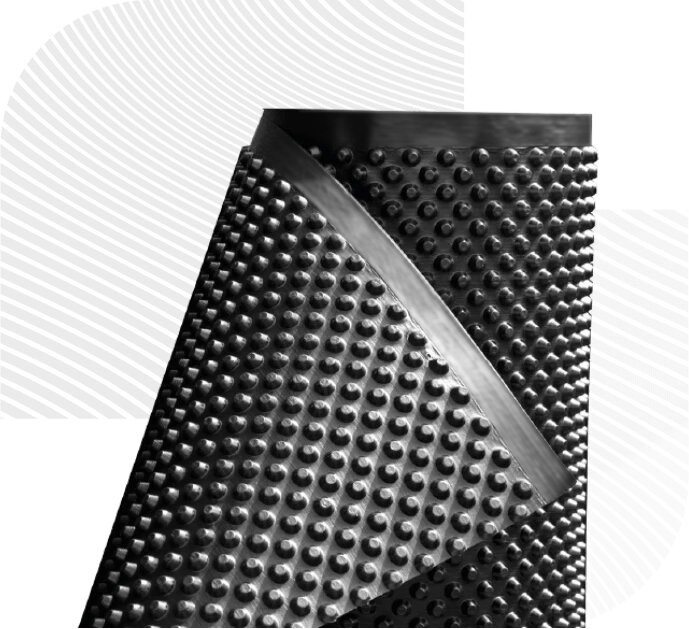

Dimpled membrane CONFOL GEO

- The embossing forms an air gap between the building structure and the insulation layer. This gap ensures perfect water and vapour removal, preventing excessive damp and development of hydrostatic pressure in building parts exposed to moisture

- The additional layer of polypropylene nonwoven textile increases the insulation strength, and its filtrating properties prevent blocking of the draining system. A perfect solution for the road construction sector and municipal investments. Dimple embossing on both sides. Geocomposite of high density polyethylene and polypropylene nonwoven textile

Find out more

Find out more

Parametry

| Grammage (g/m2) | 500 / 600 / 850 |

| Width (m) | 0,5 / 1 / 1,5 / 2 |

| Length (m) | 20 |

| Colour | black / graphite |

Application

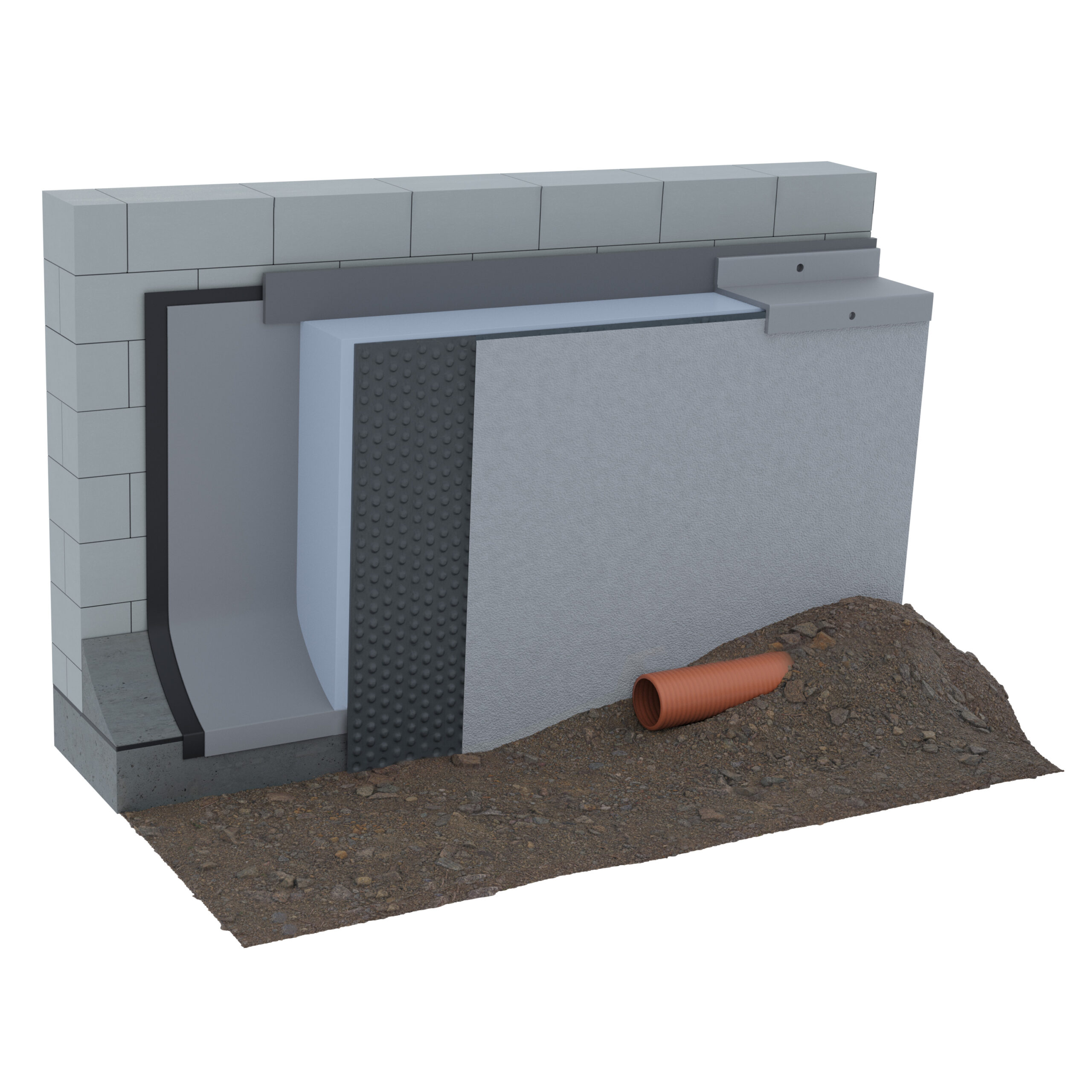

- Designated for construction of the vertical insulation layer of foundations, walls, or floorings in direct contact with the substrate

- It can also be used as an insulating layer of terraces and floors, or a draining layer in green roof structures

- Additional thermal insulation of foundation walls

Benefits

Waterproof

Durable

Broad scope of temperatures

Quality Warranty

Compression resistant

Conformity with standards

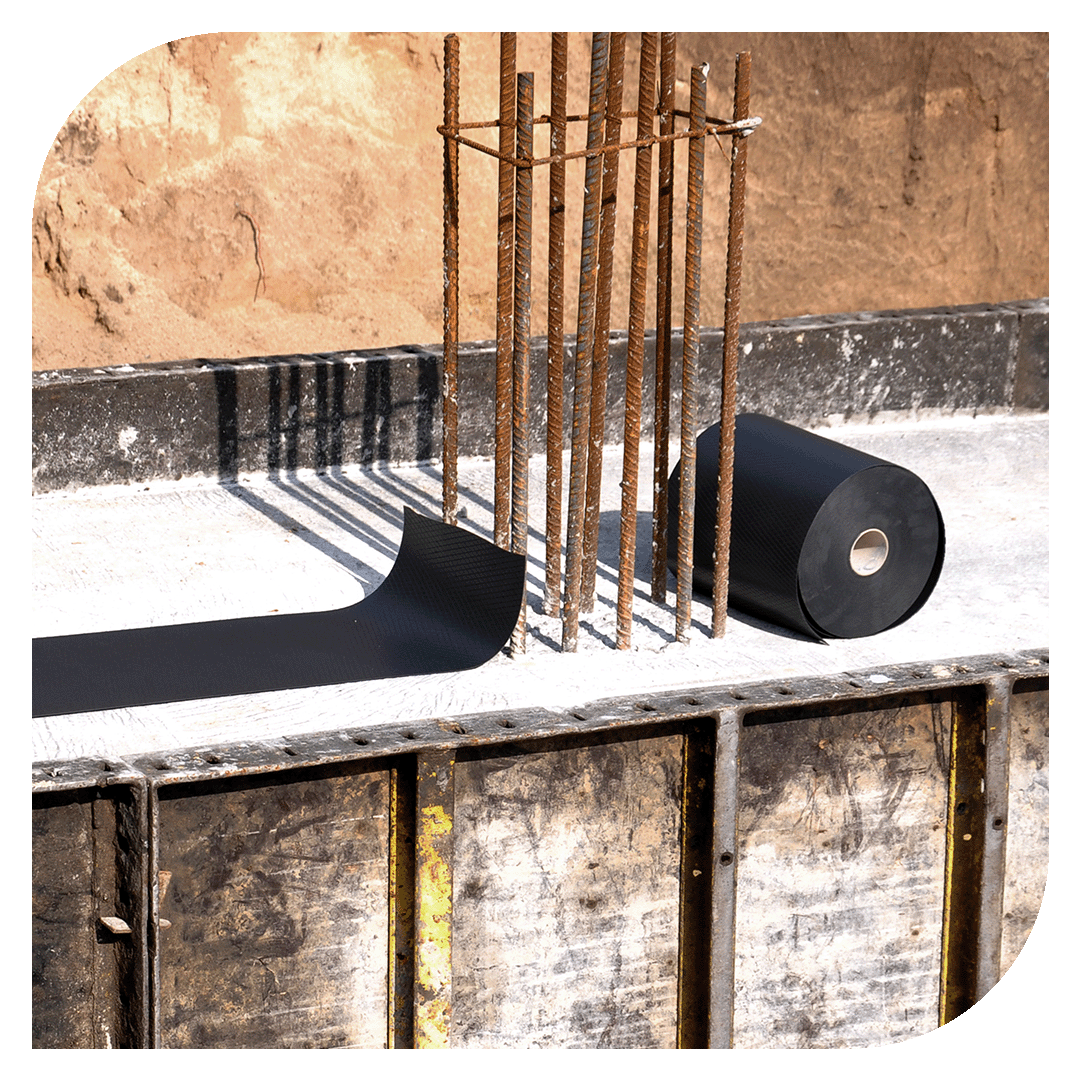

ASSEMBLY

Confol Geo foundation insulation should be installed with the filtration (nonwoven) side of geocomposite facing towards the ground outside. Film sheets should be installed with an overlap of 3–5 rows of dimples.

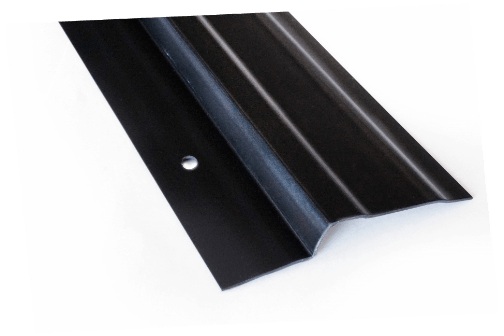

Fix the film to the foundations with nails or screws, using sealing washers. For complete protection, install a finishing strip preventing contamination penetration between the insulation layer and the substrate.

TRY OUR OTHER PRODUCTS

Conkret is a recycler and a leading manufacturer of regranulates as well as modern polyethylene films. We manage the entire technological process: starting with purchase of waste, its transport, segregation, regranulation to production of new finished products.

Our products are widely used in the furniture, packaging, construction, agricultural and gardening sectors.

More about usProces technologiczny

TWOJA KORZYŚĆ NASZA TECHNOLOGIA

Parametry uzyskiwanych produktów są zbliżone do surowców oryginalnych i znacznie przewyższają właściwości regranulatów produkowanych metodami konwencjonalnymi.

Wysokoefektywny system mycia i suszenia płatka, system filtracji ciągłej

- Brak zanieczyszczeń w wyrobie gotowym

Kaskadowy system dwuwytłaczarkowy

- Wyższa gęstość i ciężar nasypowy regranulatu

- Zmniejszona ilość pęcherzyków gazu w wyrobie gotowym

- Brak konieczności używania osuszaczy

Innowacyjny system homogenizacji

- Bardzo wysoki stopień jednorodności

- Obniżona zawartość żeli

- Polepszone właściwości mechaniczne

Automatyczny system mieszająco-uśredniający

- Stabilizacja procesu produkcji wyrobu gotowego

Certificates

WE CARE ABOUT ENVIRONMENTAL PROTECTION

The EuCertPlast (now RecyClass) certificate obtained in 2020 confirms that our regranulates are produced from post-consumer waste and their origin is fully traceable.

As active members of plastics recycling associations, environmental protection is our constant concern.

Check all

+48 56 684 24 00

+48 56 684 24 00 info@conkret.com.pl

info@conkret.com.pl