Advice

FIND ANSWERS TO YOUR QUESTIONS

The primary goal of Conkret is to create products that will fulfil the expectations of our customers. We are constantly improving our products to meet the most demanding requirements of the building insulation market. In order to achieve this, the flow of information between users and our company is essential.

Find out more

Find out more

FAQ

FREQUENTLY ASKED QUESTIONS

Question categories:

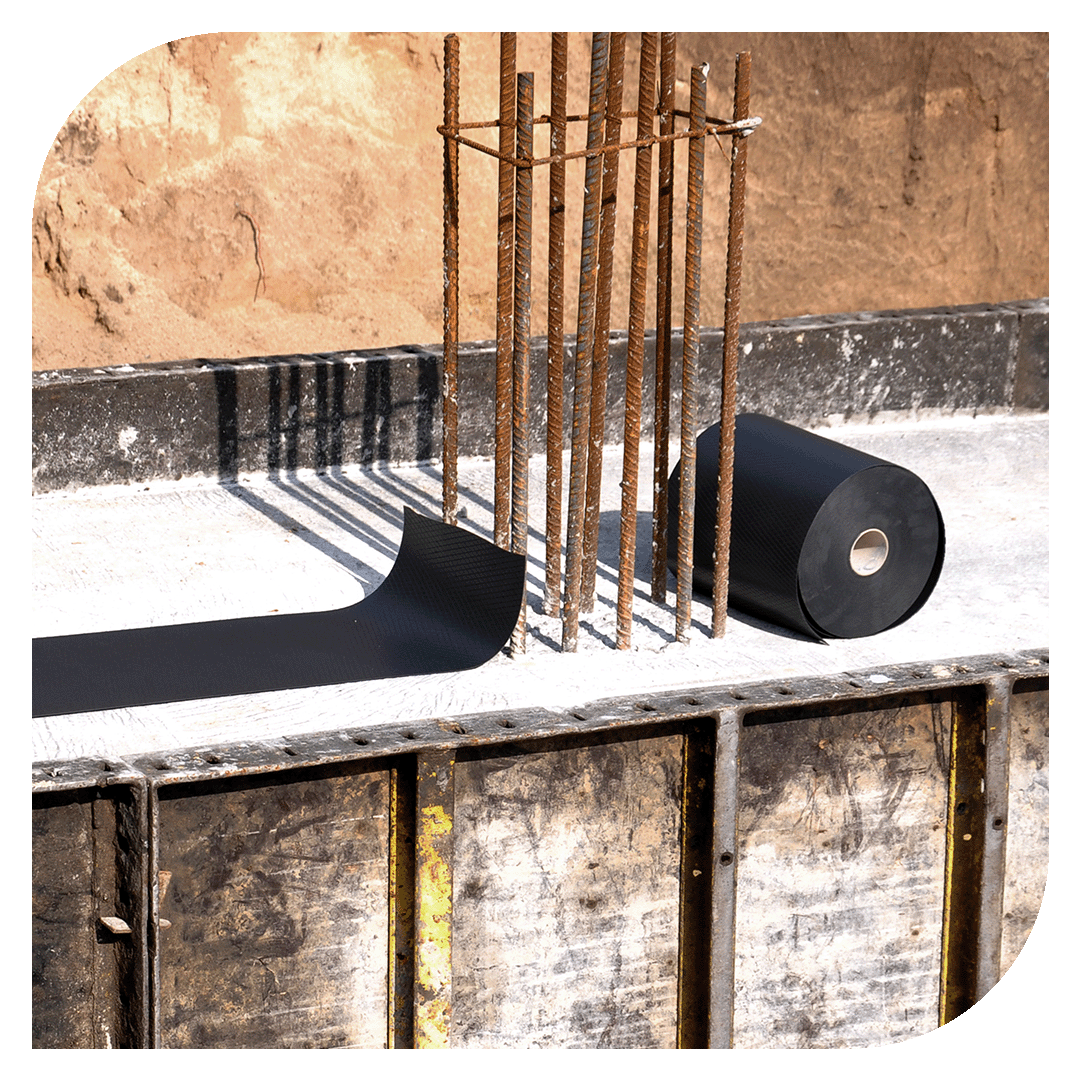

Horizontal insulation, e.g. Confol Alfa or Gamma, should be placed over the entire width of the footing, with at least 20 cm overlaps. A well-laid membrane does not require additional gluing at the joints, because the pressure of the wall is sufficient to ensure proper insulation due to the vulcanization of the membrane, but it must be tightly connected with the Conbud waterproofing.

The width of the horizontal insulation should be slightly wider than the footing. This will prevent any accidental migration of moisture.

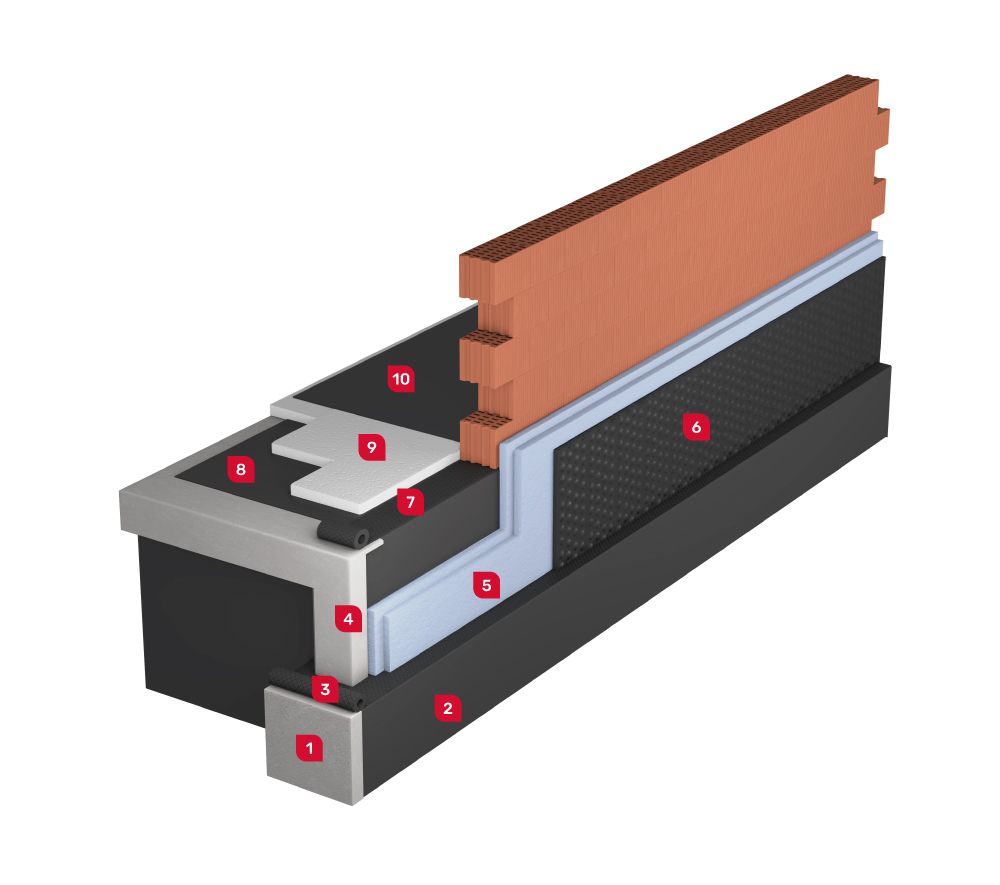

DIAGRAM:

- Strip footing

- Vertical waterproofing of foundations

- Confol Gamma horizontal insulation of foundations

- Foundation

- Foundation thermal insulation

- Confol Beta vertical insulation of foundations

- Confol Alfa horizontal insulation of foundations

- Conbud / Conbud Plus / Hydro B / Ecovil B

- Thermal insulation of the floor on the ground

- Ecobud polyethylene film

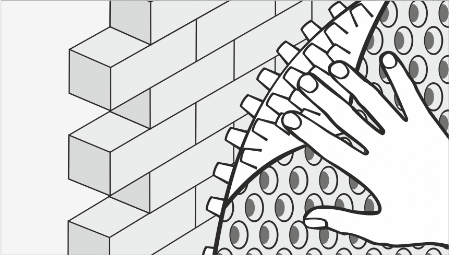

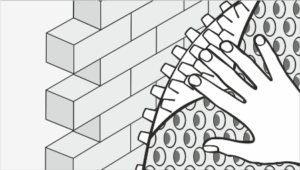

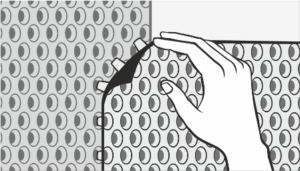

The dimpled membrane should be placed with the membrane cusps towards the foundation. Thanks to this, the soil is separated from the wall, and the air gap created supports the ventilation of the wall. The dimpled membrane should be placed on clean surfaces, devoid of elements that could damage it. Only defect-free membrane is allowed to be used.

The dimpled membrane should be joined together on the so-called overlaps with at least 3-5 rows of cusps. As a result, a tight protective barrier will be created. The cusps have been prepared in such a way that they easily fit into each other and fit together perfectly. Overlaps should be used in both horizontal and vertical connections of membranes. The insulation should be selected in such a way as to minimise the number of joints and overlaps in the place of application of the insulation.

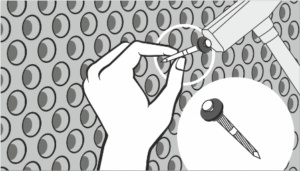

The dimpled membrane should be attached to the surface with special nails or screws, while remembering to use sealing washers. The membrane should be attached to the wall at a distance of approx. 60 cm from each other, always in the centre of the protrusion (i.e. at the point of contact with the wall).

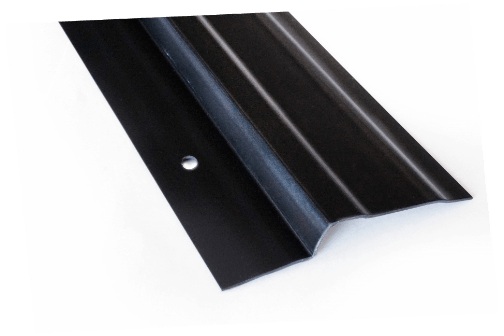

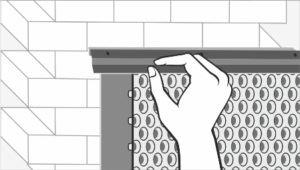

The insulation must be a continuous and sealed system that separates the building from water. For full protection, it is necessary to use a finishing strip that prevents contamination from penetrating between the insulation and the foundation. Such a strip should be used in a place where the membrane has no protrusions (i.e. on the strip ending the membrane).

DIAGRAM:

- Strip footing

- Vertical waterproofing of foundations

- Confol Gamma

- Foundation

- Foundation thermal insulation

- Confol Beta

- Confol Alfa

- Conbud / Conbud Plus / Hydro / Ecovil B

- Thermal insulation of the floor on the ground

- Ecobud polyethylene film

The waterproof membrane, when used under floors or screeds, should be placed on a previously prepared, levelled concrete base. Then connect the waterproof membrane tightly to the horizontal insulation of the walls of the Confol Alfa foundations.

Adjust the width of the membrane in such a way as to limit the connection of membranes. However, if this is not possible, the waterproof membrane should be overlapped at least 15 cm and then glued with butyl glue. The membrane should be extended approx. 20 cm up the wall.

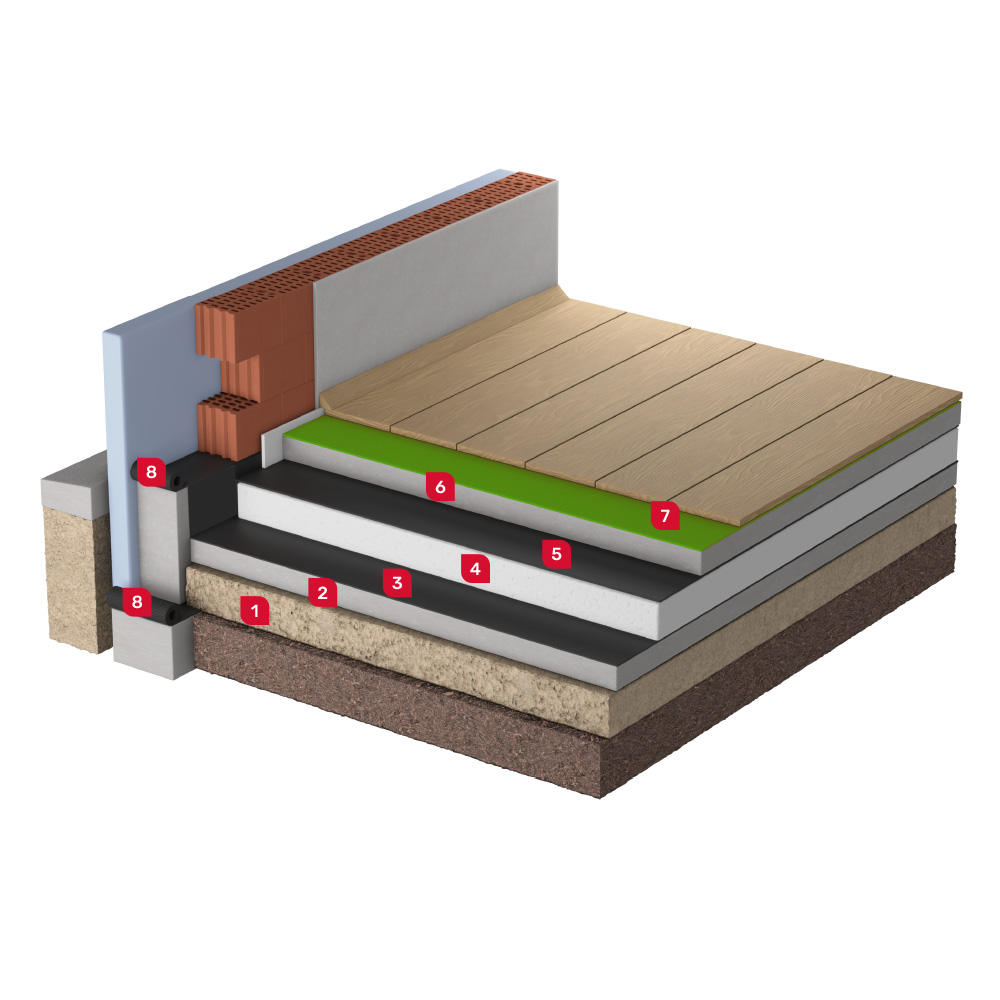

DIAGRAM:

- Levelling layer

- Construction layer of lean concrete

- Conbud / Conbud Plus / Hydro B / Ecovil B

- Thermal insulation of the floor on the ground

- Ecobud polyethylene film

- Underlay layer, e.g. screed or anhydrite

- Confloor plastic vapour barrier

- Horizontal insulation of Confol Alfa or Confol Gamma foundations

Conpar plastic vapour barrier is laid in a single layer from the inside of the roof structure vertically or horizontally in relation to the rafters. Lay the barrier with a slight tension. The vapour barrier should be overlapped with adhesive tape, and the connection with the rafter is best done with double-sided adhesive tape.

All joints of the plastic vapour barrier strips should be made with the greatest care, using at least a 10 cm overlap in such a way as to prevent the vapour barrier from becoming unsealed.

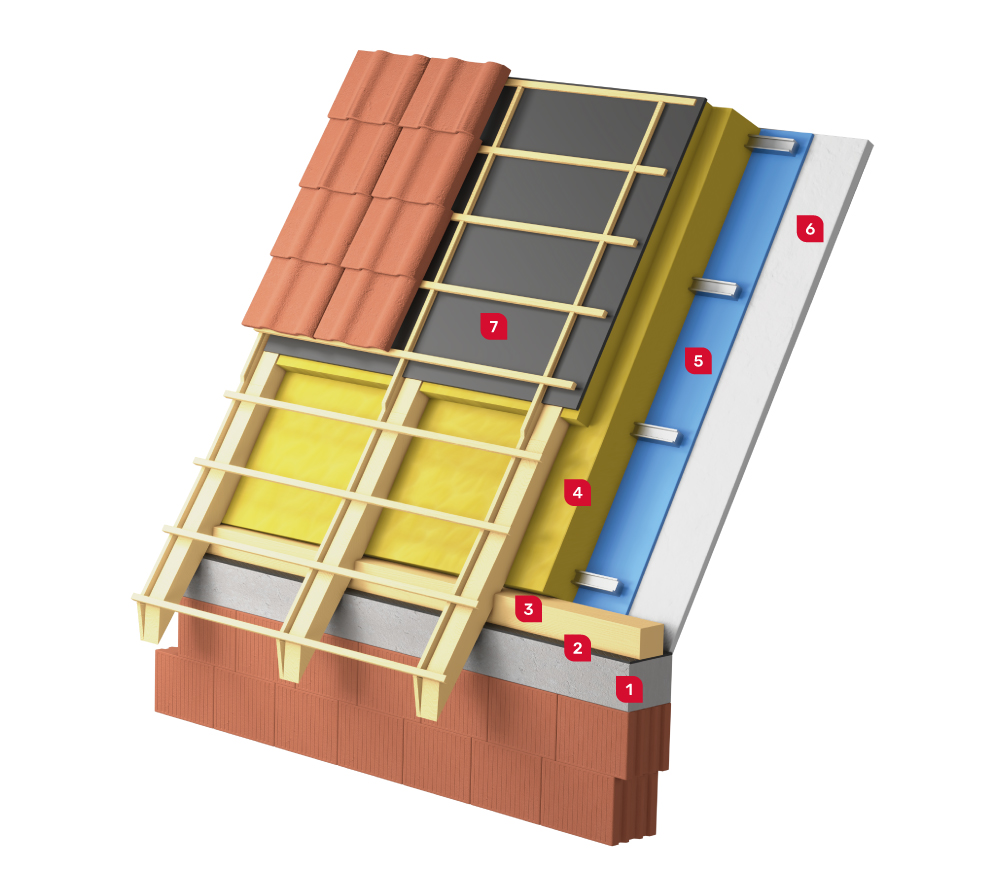

DIAGRAM:

- Roof beam

- Confol Alfa horizontal insulation of foundations

- Roof plate

- Roof thermal insulation

- Conpar / Conpar Plus / Hydro P / Ecovil P / V-Protect / F-Protect vapour barrier

- Plasterboard

- Vapour-permeable membrane

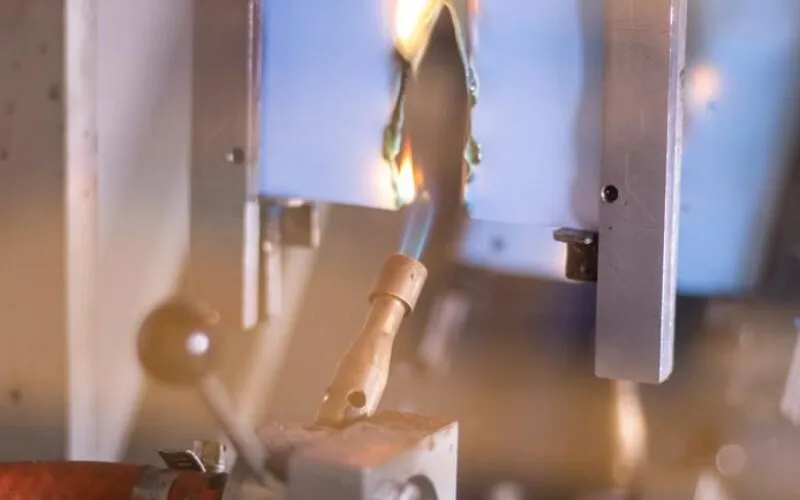

Conkret offers flame retardant membranes, e.g. V-Protect plastic vapour barrier.

This product has an increased reaction to rating – CLASS E

According to the fire classification of materials: reaction to fire according to PN – EN 13501 – 1: 2008, this means that class E does not spread fire and it is a self-extinguishing product.

The use of this membrane significantly increases the safety of the house and its inhabitants.

The height of Confol Beta dimpled membrane is 8 mm with a tolerance of +/- 7%.

Confol Beta dimpled membrane should be laid with foil protrusions towards the foundation. Thanks to this, the soil is separated from the wall, and the air gap created supports the ventilation of the wall. The dimpled membrane should be placed on clean surfaces, devoid of elements that could damage it. Only defect-free membrane is allowed to be used.

These membranes differ in tolerance. The lower the tolerance, the greater the actual membrane thickness and the better the technical parameters of the product.

Similarly, the higher the tolerance, the lower the actual membrane thickness and the lower technical parameters of the product.

Confol Alfa – from 0.3 to 0.5 mm

Confol Gamma – 1mm

The thickness of these products significantly affects the differences in technical parameters, such as nail tear strength, impact resistance, maximum tensile force and elongation at maximum tensile force.

A 1.0 mm thick membrane is a top-quality product with excellent parameters. With regard to the requirements of the EN 13967 standard, the watertightness for this membrane is 60 kPa, the tear strength is ≥ 100 N, and the percentage elongation is, respectively: longitudinal ≥ 400%, transverse ≥ 80%. The above parameters, confirmed by tests, ensure that the Confol Gamma membrane is an ideal product for horizontal insulation of foundations, which guarantees many years of failure-free operation of the building.

No. Our vapour barriers do not have an assembly side. It does not matter with which side the membrane is installed and it does not matter to its properties.

We recommend that you overlap the waterproof membrane with an overlap of at least 15 cm using:

- butyl tapes

- special tapes for joining waterproof membranes

- special glues for joining waterproof membranes

SD coefficient:

- It tells us how easily water vapour can penetrate the material

- It determines the number of grams of water vapour that is able to penetrate within 24 hours through 1 m2 of membrane

- The higher the SD coefficient, the better the membrane limits the migration of water vapour to the thermal insulation layer

- it defines in metres how thick the air layer should be in order to resist water vapour as much as the membrane

- Vapour barrier products have an SD in the range of 20 – 149 m, products rated > = 150 are vapour-tight products

- The lower the SD value, the lower the resistance, which results in greater penetration of water vapour through the material

- The higher the SD value, the greater the resistance, and the better it limits the migration of water vapour to the thermal insulation layer

Simply put, it determines the effectiveness of the protective layer. For example – an SD at the level of 50 metres means that the membrane is a barrier for water vapour as 50 metres of air would be.

Holes in the membrane should be covered with specially designed tapes for waterproof / vapour barrier membranes.

No, Conbud membrane has not been tested for use as a vapour barrier. Certified vapour barriers must meet the requirements of PN-EN 13984, while waterproof membranes such as Conbud meet the requirements of PN-EN 14909.

Protective film under the lean concrete will not protect it from moisture from the ground, but it will prevent the flow of bleeding water milk into the sand and gravel mix.

- as protection against the effects of external factors such as: dust, water

- for securing work stations, building materials, and excavations

- it can be used for temporary protection of thermal and acoustic insulation against moisture

- temporary protection of agricultural produce

When securing construction works in attics, it is better to use a yellow protective film for the comfort of work. The yellow film may make the room brighter and it will heat up less than when using black protective film.

LDPE regranulate is a material that results from the processing of polyethylene products. The resulting raw material is used for the production of subsequent products. The use of polyethylene regranulate is basically unlimited – it can be used to produce both machine elements and simple shopping bags. Below we will try to show some typical applications of this type of regranulate.

Definitely YES, by producing using our LDPE regranulates, we give waste a second life.

The product we offer to our customers is granulate obtained by recycling LDPE waste. It is the basis for the production of various types of foil, plastic packaging, stretch, pipes and buckets.

The production of our Contalen regranulate is in line with the concept of the Circular Economy, aimed at the reasonable use of raw materials and reducing the negative impact on the natural environment.

Real benefits of recycling plastics:

- reducing CO2 emissions by up to 90% and having a positive impact on climate change

- best alternative to fossil raw materials

- reducing dependence on natural resources (natural gas, oil)

- limiting the release of plastic waste to the natural environment

- no combustion or storage of plastics leading to the release of poisonous toxins and gases

- wide use of recyclates from food contact containers to aesthetic automotive components

- setting trends and strongly advocating environmental protection leading to legislative changes, the new PCR directive and Extended Producer Responsibility

- traceability, standardisation, regulated standards and transparency regarding the processing of plastic waste

- creating new chains of cooperation and values

- development of new technologies, automation and process-oriented activities

MFI – Melt Flow Index is a number expressing the amount of thermoplastic material flowing through a circular nozzle with a predetermined size: within a certain time, under a given pressure and at a given temperature.

Due to the type of raw material from which the LDPE regranulate is obtained, it is possible to separate a clean product and a straw product. Straw LDPE regranulate is made of LDPE film waste. Clean LDPE regranulate is one that was made of better quality products (neither damaged nor contaminated). It is then used to produce films for plants, plastic containers for cosmetics, or transparent shopping bags. These products can be transparent or have a specific, nice colour. The most common colors are black, red, green, yellow and blue. An example of a good-quality product is Contalen regranulates (more information at contalen-recycling.com). These are polyethylene regranulates that are durable, light, cheap, resistant to mechanical and thermal damage, as well as suitable for transport and storage in various conditions.

LDPE regranulates are made of previously cleaned and segregated waste, brought to a loose form. Grinding the products takes place in special machines that dry them thoroughly at the same time. The quality of the produced LDPE regranulates is determined not only by the advancement of the machines used in production, but also by the raw material from which the polyethylene regranulate is made. The better the base material, the better the final quality of the regranulate. The way the processing plants work is also important: the ability to properly filter, and sufficiently dry the raw materials. Only professional companies are able to provide a product that complies with the design specified by the customer.

LDPE regranulates offer almost unlimited possibilities of use. They can be used to create ecological products, fit into the circular economy, and reduce the final production costs. If you find an appropriate supplier of good-quality regranulate, you will obtain a semi-finished product that is much cheaper than the plastic manufactured “from scratch”.

- Plastic dpc sheets (foundation insulation, waterproofing, vapour barrier)

- STRETCH heat-shrinkable films

- Agricultural and horticultural films

- Packaging film

- Plastic bags

- Garbage bags

- Foil tunnels

- Soft bottles

- Tapes

- Pipes

- Buckets

- Plastic boxes

Our technology guarantees:

- no impurities in the final product

- higher density and bulk density

- the minimum amount of bubbles in the finished product

- The production does not require the use of desiccants, while reducing the amount of gels

- high degree of homogeneity

- improved mechanical properties

- impact on the development of the circular economy

- responsibility for the environment

- 100% recycled ecological material solution

- the highest quality and parameters similar to the original raw material

Contalen 0031 is a linear low density polyethylene derived from post-consumer stretch film waste, intended for the production of extrusion blow films, cast films and injection moulding. Films made of Contalen 0031 show excellent puncture resistance, high tensile strength and good weldability.

Application:

• Heat-shrinkable films

• Agricultural films

• Transport bags,

• Co-extruded films

• Bags

• Industrial packaging

• Shrink hoods

• Plastic dpc sheets

• Garbage bags

Contalen 0050 COF are LDPE homopolymers containing LLDPE intended for extrusion and injection of film by blowing and pouring. It has excellent processing properties. Contalen 0050 COF is suitable for the production of films above 20 microns, which are characterised by very good mechanical properties.

Application:

• Preparation of mixtures

• Bags (plastic bags)

• Co-extruded films

• Plastic dpc sheets

• Packaging film

• Masking film

• Industrial packaging (furniture packaging)

• Baggies

• Garbage bags

• Agricultural films

Contalen 0051 ACP is an LDPE homopolymer designed for film extrusion by blowing, pouring and injection moulding. It has excellent processing properties. Contalen 0051 ACP is suitable for the production of films above 40 microns. Films made of Contalen 0051 ACP are characterised by very good mechanical properties. Due to the low flow index, it is characterised by very high mechanical strength and high puncture resistance. The main purpose is the production of very high-strength heat-shrinkable films for which a very high degree of shrinkage is required.

Application:

• Heat-shrinkable films

• Agricultural films

• Transport bags

• Co-extruded films

• Bags

• Industrial packaging

• Shrink hoods

• Plastic dpc sheets

• Garbage bags

- DURABILITY

The mounting strip for dimpled membranes is made of plastic (PVC or HDPE) resistant to weather and mechanical conditions. It is also chemically resistant to substances naturally occurring in the soil and used in construction. - HELPS TO KEEP THE MEMBRANE WATERPROOF

Thanks to the use of a mounting strip for dimpled membranes, they can maintain the mechanical properties of the membrane declared by the manufacturers. - PROTECTS THE DIMPLED MEMBRANE AGAINST MECHANICAL DAMAGE

The mounting strip for the dimpled membranes presses the membrane to the foundation during its assembly, which is its perfect protection against mechanical damage. - PROPER PRESSURE OF THE MEMBRANE

Due to the appropriate stiffness and profiling of the dimpled membrane, the mounting strip for the membrane ensures optimal pressing of the membrane to the foundation. - PREVENTS FUNGAL DECAY OF WALLS

Mounting strip for dimpled membranes insulates the upper part of the membrane, which prevents water flowing down the wall from getting between the foundation and the membrane, effectively increasing the drainage efficiency, which protects the building against fungal decay. - PREVENTS DAMAGE TO THERMAL INSULATION AND FACADE

The mounting strip for dimpled membranes prevents water and sand from penetrating between the insulation and the wall insulation, thus preventing damage to the facade and thermal insulation. - PROTECTS THE FOUNDATION

The mounting strip for the dimpled membranes prevents the penetration of contaminants between the membrane and the foundation, ensuring free air movement and evaporation of excess moisture at the same time. - IMPROVES THE LIFE OF THE DIMPLED MEMBRANE

The mounting strip for the dimpled membrane, thanks to the attachment of the membrane during construction, reduces the possibility of bending, breaking and other ways of damaging the membrane by mechanical or atmospheric factors. - EASY ASSEMBLY

The mounting strip for dimpled membranes is properly profiled so that its assembly is easy and effective. The upper part (25 mm), which has holes for fastening drilled every 16 cm, is used to fix the strip to the wall. The lower part (45 mm) covers the membrane, holding it and pressing it down properly. - AESTHETIC FINISH

The mounting strip for dimpled membranes is an aesthetic finishing element, durable, made of resistant material, lasting many years.

In Poland, westerly winds prevail and when they blow when it rains, water hits the walls of the building and runs down their surface. It is easy for it to get under the dimpled membrane, if you do not install a strip for this membrane there first, which will close this space from the top.

The mounting strip for the dimpled membranes insulates the upper part of the membrane, which prevents water flowing down the wall from reaching the foundations, which protects the building against fungal decay.

The strip for securing the membrane is one of the cheapest insulations during the construction of the house.

On construction sites, it can often be seen that where no protective strip was used, the drainage gap between the dimpled membrane and the foundation was already clogged with sand and other debris by the time construction was completed and the building was put into service. Such a situation may significantly affect the condition of the foundation wall. As a consequence, it may be necessary to replace the entire foundation insulation, which severely increases the investment costs.

Dimpled membrane nails have special sealing washers, thanks to which a properly mounted nail creates a tight connection of the foundation membrane with the surface to which it is mounted. Moreover, the nails are made of hardened carbon steel, electro-galvanised and have a conical head and a rolled shank.

Advice

COULD NOT FIND THE ANSWER TO YOUR QUESTION?

If you can find no answer above to your question - write to us. We will make sure to respond as soon as possible.